+1(909)680 0546

Metal Shredder

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-28 Origin: Site

Metal chipper shredders play a crucial role in efficient metal recycling. Their precision and efficiency are key to turning waste into valuable resources. Why does high precision matter in metal shredding? Precision ensures better output quality and enhances recycling efficiency. In this post, we'll explore how high precision and efficiency in metal shredders contribute to sustainability and smarter recycling.

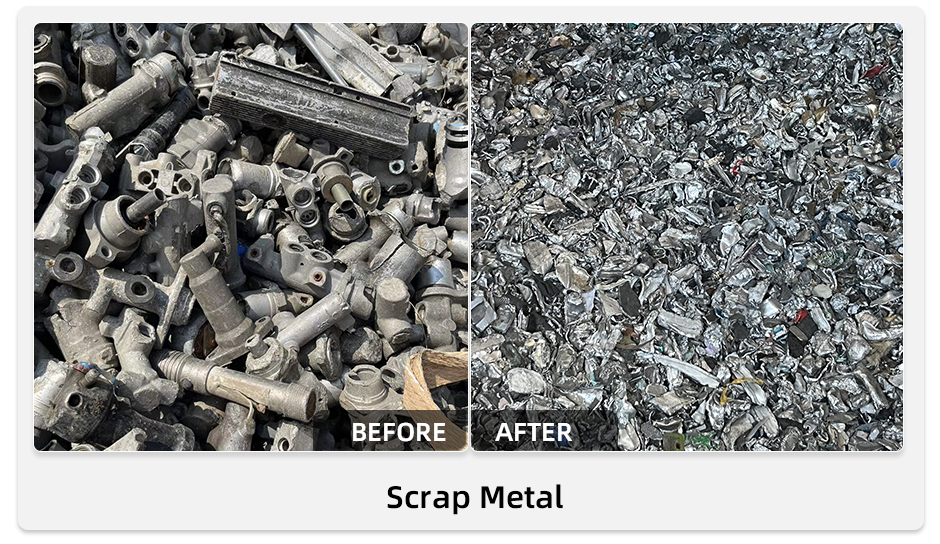

A metal chipper shredder is a powerful machine designed to break down scrap metal into smaller, more manageable pieces. These machines are essential in recycling processes, as they help reduce bulky metal waste into uniform pieces.

In metal recycling, shredders play a vital role in processing scrap metal, including steel, aluminum, and copper. They help separate useful materials from non-metallic waste and reduce the overall volume of scrap. By breaking down large metal items like old vehicles and industrial waste, shredders make it easier to transport and further process materials for reuse.

A typical metal shredder has several key components, each contributing to its efficiency and precision.

Rotor: The rotor is the heart of the shredder. It uses high-speed rotation to break down materials. The design and speed of the rotor determine how effectively the shredder processes metal.

Blades: These sharp, heavy-duty components cut through metal with precision. The choice of blades depends on the type of material being shredded.

Motor: The motor provides the power needed for shredding. A powerful motor ensures the shredder can handle tough materials without slowing down.

Housing: The housing encloses the rotor and blades. It protects the internal components and helps direct shredded material into a collection area.

Each of these parts works together to ensure the shredder performs efficiently, with minimal wear and consistent results. The precise design of these components contributes to the high efficiency and long-term durability of metal chipper shredders.

High precision in metal shredding is achieved through meticulous manufacturing. It ensures that the shredder produces uniform, accurate output every time.

Machining processes like CNC milling and laser cutting are commonly used. CNC milling automates metal shaping with extreme accuracy, while laser cutting delivers precise, fast cuts without wear on tools.

Automation plays a key role in enhancing operational efficiency. It reduces human error and ensures shredders perform consistently, even in demanding conditions.

Smart systems now allow users to monitor and control shredder operations remotely. These features help optimize performance, adjust settings in real time, and diagnose issues before they become problems.

Energy-saving features are critical in modern shredders. By reducing energy consumption, these machines lower operational costs while reducing their environmental impact.

Efficient shredders use less power to process the same amount of material, making them more cost-effective and eco-friendly. This not only cuts electricity bills but also contributes to a greener, more sustainable recycling process.

Precision in manufacturing directly affects throughput. The more accurate the shredder's components, the faster and smoother the shredding process.

High precision reduces delays caused by malfunctions or inconsistencies, allowing for quicker processing times and increased overall productivity.

Shredders built with precise components and durable materials last longer. High-quality manufacturing ensures that parts fit perfectly, reducing wear and tear.

Durable materials, like high-strength alloys, help prevent breakdowns, ensuring the shredder continues to operate effectively for years.

Using high-precision metal shredders promotes eco-friendly recycling. These shredders reduce waste by ensuring more material is recycled efficiently.

They also help lower the carbon footprint. By maximizing output and minimizing energy use, they contribute to a more sustainable circular economy.

Precision plays a critical role in the effectiveness of metal shredders. It ensures that the shredded output is uniform and consistent, which is crucial for downstream processes like sorting and processing. With precise cuts, the material is easier to handle, and the chance of contamination from unwanted pieces is minimized.

Accurate cutting also helps reduce unnecessary wear on the shredder. When parts are precisely manufactured, they fit better and experience less friction, leading to a smoother operation and fewer maintenance needs.

High-precision shredding significantly improves the overall metal recycling process. It ensures that materials are shredded into consistent sizes, which makes it easier to sort ferrous and non-ferrous metals from other materials.

The quality of the shredded metal matters greatly. High-quality shredded material is more efficient to refine and recycle, increasing its potential for reuse in manufacturing. This leads to higher yields and greater efficiency in the recycling industry, helping to keep more materials in circulation and reducing the need for new raw materials.

Single-shaft metal shredders are perfect for processing smaller, softer metal scraps. These machines use a single rotor to break down materials into manageable sizes.

They are commonly used in scrap metal recycling facilities for processing aluminum, copper, and light steel. Their straightforward design makes them easy to maintain and operate.

Double-shaft shredders are built to handle larger and tougher materials. They offer high torque and low-speed operation, which helps efficiently shred heavy-duty metals like thick steel or car parts.

These shredders are ideal for situations where higher power and stronger cutting ability are required. Their robust design reduces the risk of jams, even with challenging materials.

Four-shaft shredders are the go-to choice for heavy-duty applications, such as shredding old vehicles or industrial waste. They offer higher throughput and precise size control, making them suitable for high-volume operations.

These shredders are equipped with multiple rotors, allowing them to handle tougher waste while providing finer output for further processing. This makes them perfect for demanding industries requiring consistent results.

● Three-Shaft Shredders: These machines have three rotating shafts, providing high-efficiency shredding. They're designed for versatile applications and can handle a wide range of materials.

● Horizontal & Vertical Hammer Mill Shredders: These shredders use heavy hammers to repeatedly strike and crush materials. Horizontal models are great for large metal items, while vertical models excel at processing small, hard metals.

Each type offers unique features, designed to meet different processing needs in metal recycling.

Throughput refers to the amount of material a shredder can process in a given time. It directly impacts the efficiency of your operation. A higher throughput means faster processing, but it also needs to match your specific recycling needs.

When choosing a shredder, consider the volume of material you'll be processing. For large-scale operations, a shredder with higher throughput is necessary, while smaller operations can work with a lower throughput model.

Evaluating the energy efficiency of a shredder is crucial. Energy-efficient shredders consume less power while still providing high performance. This reduces electricity costs and can lead to significant long-term savings.

Look for shredders that offer energy-saving features like optimized motor speeds and automatic power adjustments. These features help reduce energy use and lower operational costs.

Different types of metals require different shredder configurations. Lighter metals like aluminum are easier to shred, while harder materials like steel need more power and specialized blades.

Make sure to match the shredder to the materials you'll process. For tough metals, a machine with higher torque and robust components will be necessary to handle the extra stress.

High-precision shredders are designed to require less frequent maintenance. The better the manufacturing, the fewer the chances of malfunction or wear.

Choose a shredder that offers durable, high-quality components. Long-term durability reduces the cost and time spent on repairs and part replacements, saving money in the long run.

Regular maintenance is crucial for keeping your shredder running efficiently. It ensures precision and reduces the chances of costly breakdowns.

● Blades: Keep them sharp to maintain cutting efficiency. Dull blades can slow down the shredding process and cause uneven cuts.

● Motor: Regularly check the motor for signs of wear or overheating. A well-maintained motor runs more efficiently, saving energy and reducing stress on other components.

● Rotor: Inspect the rotor for any damage or imbalance. An imbalanced rotor can lead to inefficiency and higher maintenance costs over time.

Integrating smart features can significantly improve operational efficiency. Many modern shredders come equipped with sensors and control systems that help monitor and adjust performance in real time.

● Remote Diagnostic Tools: These tools allow you to troubleshoot problems from a distance, saving time and reducing downtime. They can alert you to issues before they become serious, allowing for quicker resolutions.

How you handle the material going into the shredder directly impacts its performance. Improper loading can cause jams or slow down the process.

● Correct Loading: Make sure materials are loaded evenly to avoid overloading certain parts of the shredder.

● Feed Rates: Monitor the feed rate closely. Feeding too quickly can cause blockages, while feeding too slowly can reduce the shredder's throughput.

High precision metal shredders play a significant role in reducing waste and promoting sustainability by efficiently breaking down metals for recycling, which helps reduce landfill waste. Energy-efficient shredders use less power, minimizing their carbon footprint and lowering greenhouse gas emissions. Additionally, these shredders contribute to the circular economy by reclaiming valuable metals, ensuring materials stay in use and out of landfills.

High precision and efficient metal chipper shredders are crucial in modern recycling for reducing waste and enhancing productivity. Choosing the right shredder depends on your specific needs, whether it's throughput, energy efficiency, or material type. Investing in high-quality shredders ensures better performance, cost savings, and contributes to a more sustainable future. Welcome to ENERPAT Consulting Products!

A: Metal chipper shredders can process a variety of metals, including aluminum, steel, copper, and alloys, depending on the shredder type.

A: Regularly check the motor for wear, clean it, and ensure it's properly lubricated. Monitor for overheating and replace worn parts as needed.

A: While primarily designed for metals, some shredders can handle certain non-metallic materials, but it depends on the shredder's configuration.

A: A high-precision shredder can last for many years with proper maintenance, typically 10-15 years or longer.